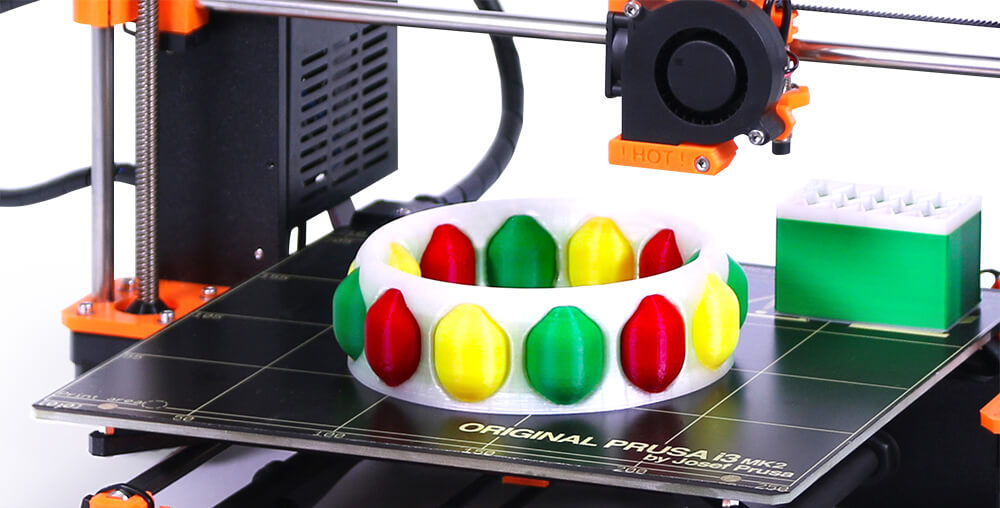

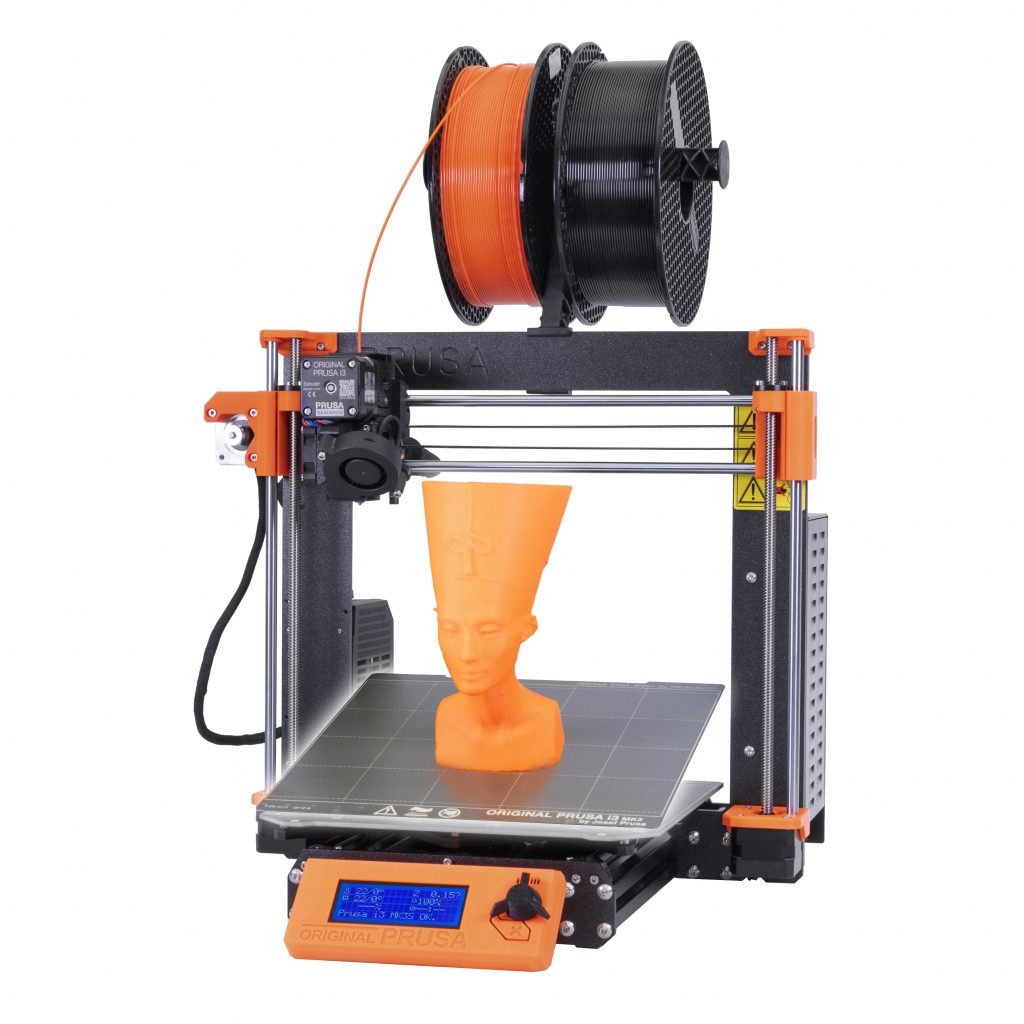

This way you only need 1 pass to make a 0.8mm wall. Using the existing settings of your previous print, you can lower 5-15 C.Ĥ) Wide range of nozzles sizes (mm) available from 3D Solex:Ġ.25, 0.40, 0.50, 0.60, 0.80, 1.0, 1.2, 1.5, 2.0Įxample: You can now print a vase with a 0.80mm nozzle at the same or higher speed than you could using a 0.40mm nozzle previously. Since you are effectively melting the plastic you can print at a lower temperature than before. Change nozzle in seconds, without risk of destroying the sensors of the printer or the heat break.Ģ) Print with a much higher troughput, by configuring a combination of :ģ) Print with a lower temperature.

#PRUSA I3 OZZLE FREE#

Advantagesġ) You can now change nozzle risk free and hazzle free, by using the tool available separately. Hot or cold, you can use the drill itself to ream, but be very cautious as you may widen the nozzle itself doing this. 8 nozzle profiles (also in the printer settings), lowered the speed and - fool mode on - intuitively changed some other parameters at will and with a 'let's see attitude'. We suggest decreasing the speed to about 75 for first three layers, then return it to normal.

Anti-clockwise decrease speed, Clockwise increase speed.

#PRUSA I3 OZZLE HOW TO#

The easiest way how to do it is by rotating the knob during the printing process. You can use the back end of a microdrill bit. i bought a 1,4 mm v6 compatible nozzle for my mk3s+ (stock parts, no tuning) and did not really find answers on the right parameters. Decrease the printing speed If everything above failed, then try decreasing the printing speed. Raise the extruder as high (Z-axis) as you can, heat, and use a properly-sized stiff wire to ream out the nozzle. What the others must do: Lengthening the heating zone, which has a negative effect on retractions, adds weight to the head and is costly. Alternatively, don't bother removing the nozzle. The core heating effect of the Matchless nozzles is melting the middle of the filament, that part which you wish to push out through the nozzle. An ordinary nozzle is melting the filament from the “outside” and trying to push the coldest part (centre of filament) through the exit hole of the nozzle. The Matchless nozzles, patented by 3D Solex, have a melting zone much bigger than an ordinary nozzle. This Nozzle allows “volcano-speeds” by just changing the nozzle (0.25 makes no difference). Recommended tool: Nozzle Changer for Prusa I3 What it does The Prusa i3 MK3S+ has a 0.4 mm nozzle, which provides higher speed and better quality of printing. Ook kan de filament sensor een verstopte nozzle ontdekken, dit maakt de kans op. This ensures that you can change nozzles without fear of destroying the heater block. De Prusa i3 MK3S+ Kit is geheel vernieuwd en ook nog eens super slim. The nozzles are brass, and are coated with a layer to prevent them from reacting with the aluminium block. Ramp up plastic output thanks to our patented core heating nozzles and fully utilizing the Bondtech feeder already installed in your printer. By combining nozzle size, layer height and speed you can achieve up to 30 cubics / second.Ġ.25 mm (not Matchless, as the core heating will have little effect at the low throughput of this tiny nozzle)

0 kommentar(er)

0 kommentar(er)